Opting for an alternative design or tool, using a tool that comes with a cushioned grip, or modifying a tool are options for reducing the force needed when using these tools and the risk for injury.

- Depending on how you hold the tool, you may be able to modify your tool's grip area by adding padding to the handle or grip area, such as the ViscolasOrthex™ Grip Kit, to increase the size of the grip area. Wearing gloves may also help create a cushion and increase the size of the handle or handle area. Depending on the materials and products you are working with a specific type of glove may be recommended or required to protect your hands from skin disorders, such as burns and dermatitis, or other injuries. Note: some workers have reported a reduced sense of touch and needing a stronger grip when wearing gloves. Using a hand tool with a non-slip grip area or adding an anti-slip material may help

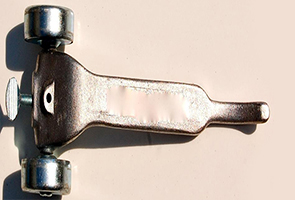

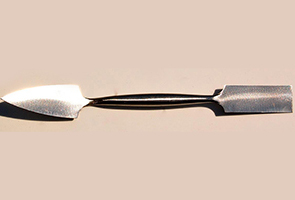

- Some of these tools come equipped with padded handles or handle areas, such as the Marshalltown Steel Body Skate Raker* or the EzyMix Detail Tool - Small* which, according to their website, is available in 10, 12, 15, 20, 25mm wide.

- An alternative design, for example, jointers with distinct handles, such as the Marshalltown 1/2 x 1/8 Bit-Grapevine Jointer w/DuraSoft® Handle,* allow you to use the tool with a modified power grip, which is much less tiring.

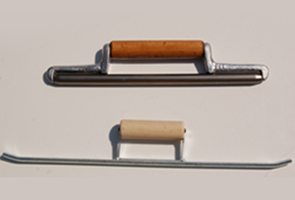

In some instances a sled runner (photo 4) may be an alternative to a jointer to finish mortar joints. Use of a sled runner will allow you to use a power grip, which can reduce discomfort, fatigue, and risk of the hand or wrist injuries associated with using a precision grip. The downside is that sled runners are heavier, bulkier to carry and, unlike two-ended jointers, cannot be used to cut off excess mortar and the blade is all one size.

If you use a different tool, such as a sled runner, it is important to consider the following:

- The grip should match or be close to your grip size.

- Since the handle is positioned over the blade, you need to make sure that the grip size leaves enough clearance between the handle and the blade for your knuckles, while still having a comfortable grip. Handles that are curved or slightly tapered under the middle of the handle may help.

- A cushioned handle may reduce pressure on your palm.

- If the tool's handle or grip area is too large and made out of wood, you might be able to sand it down to a smaller grip size. But be careful, sanding too much off could affect the strength of the handle and increase the chance of it breaking.

If you already have a hand/arm injury or condition such as tendonitis, arthritis, or carpal tunnel syndrome, it is particularly important to try to reduce the grip force as much as possible. Cushioned non-slip handles or handle areas, and/or use of alternative tools or ones with distinct handles can reduce the grip force needed. Selecting a tool that keeps your wrist as straight as possible is also important.

Example:

Worker Hand Measurements = hand size (length) of about 7-1/2" (or 7.5"), with a grip diameter of about 1-1/2" (or 1.5"), a grip size of about 4-7/10" (or 4.7"), and a palm size of 3".

Choices:

1/2" & 5/8" convex jointer; flat grip area – 3/4" width on each side, all metal, grip area length 2", total tool length 11", and weight 5.2 oz.

OR

1/2" & 5/8" convex jointer that is split into two tools with distinct handles, grip at widest point 3-7/8", a 4-1/2" handle length, total tool length 9-1/4", and weight 8.8 oz (for both).

What the worker in this example should consider:

- The plus side of using a jointer with a distinct handle is that it allows the worker to use a power grip, which can reduce discomfort, fatigue, and risk of hand or wrist injuries associated with using a precision grip.

- While the handle's grip is smaller than the worker's grip size in this example, it could be modified by adding a cushion (with a tool padding kit), which would also help reduce the amount of strength needed, fatigue and risk for injury. The downside is that the worker will now have to switch tools and their tool bag will be slightly heavier due to the added weight of the handles.